Top 7 Tube Cleaning Brush Techniques Professionals Swear By

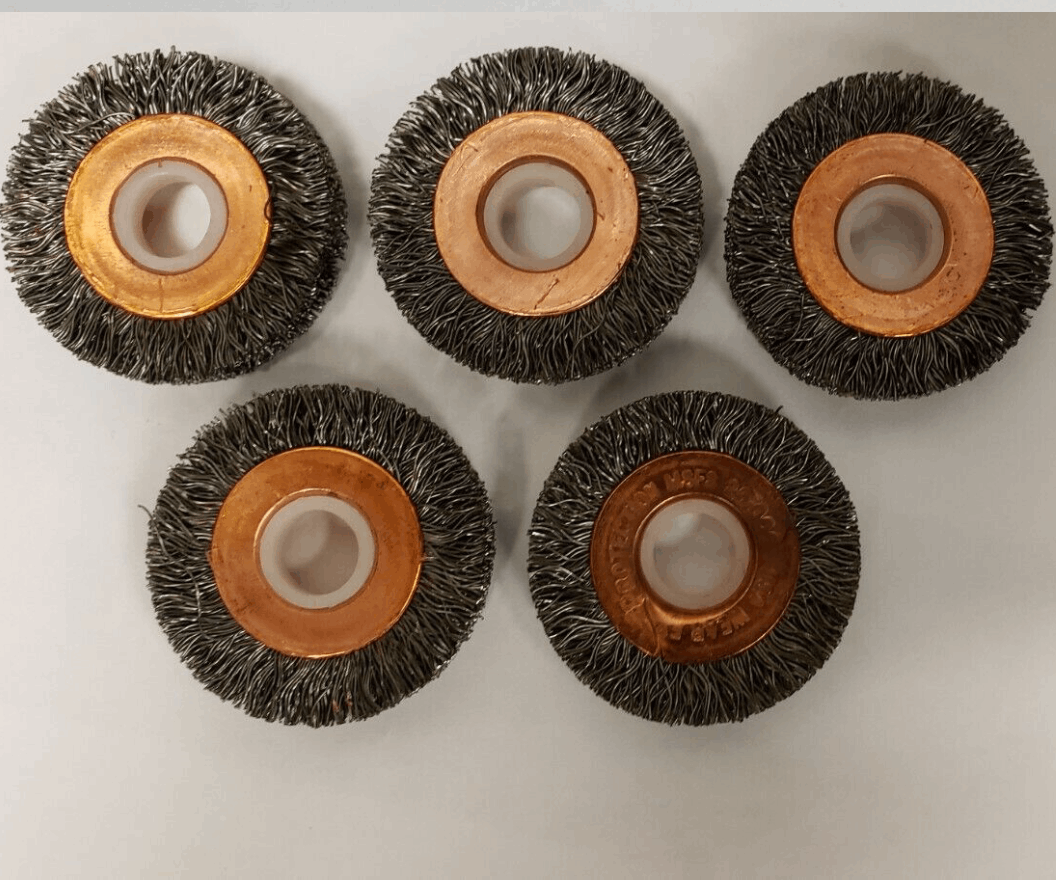

Keeping tubes clean is important in many industries, from labs to factories. Dirty or blocked tubes can slow down work, affect safety, and lower product quality. Professionals know that the right tools and techniques make cleaning easier and faster. High-quality tube cleaning brushes are essential to get tubes spotless.

Some types, like brushes with shanks, help reach tight spots and give better control, making the cleaning process smooth and reliable.

1. Circular Motion Cleaning

One of the easiest and most effective methods is the circular motion. Insert the tube cleaning brush into the tube and rotate it steadily. This scrubs the inside evenly and removes dirt without damaging the tube. Circular motion works for tubes of all sizes, from small lab glassware to industrial pipes. Keep your movements steady and maintain light pressure to get a consistent clean.

2. Back-and-Forth Technique

For tougher dirt, the back-and-forth method works well. Push the brush fully into the tube and slowly pull it out while scrubbing. Repeat this a few times until the tube is clean. This ensures every part of the tube gets attention. Professionals often use this method with circular motion for extra cleaning power. Strong bristles prevent debris from sticking to the tube walls.

3. Soaking and Brushing

Some tubes carry residues that are hard to remove with brushing alone. In such cases, soaking the tube in a suitable cleaning solution first softens the debris. After soaking, use tube cleaning brushes to scrub away the loosened dirt. This method saves time and gives a thorough clean. It works especially well for glass tubes, medical equipment, or tubes prone to scaling or chemical buildup.

4. Using Flexible Brushes

Flexible brushes are ideal for tubes with bends, curves, or unusual shapes. They adjust to the tube’s contours, ensuring no spot is missed. Flexible tube cleaning brushes are widely used in plumbing, HVAC systems, and labs. Professionals rely on them to reach corners that standard brushes cannot. Choosing the right size and flexibility helps achieve a clean surface every time.

5. Multi-Pass Cleaning

Some professionals use several brushes of different sizes to clean thoroughly. Start with a smaller brush to reach narrow areas, then use a larger brush to cover the full tube. This multi-pass approach ensures even hard-to-reach areas are cleaned. It’s a technique preferred in industries with high cleanliness standards, like food processing, chemical labs, and pharmaceuticals.

6. Combination with Compressed Air

Combining brushing with compressed air is another effective method. After brushing, professionals blow compressed air through the tube to remove loosened dirt. This step ensures nothing remains stuck inside, especially in long or narrow tubes. Using air with brushing reduces extra effort and leaves tubes cleaner.

7. Twisting Action

For stubborn residues, a twisting motion works well. Insert the tube cleaning brush and twist it while moving it through the tube. This scrapes off dirt while covering the surface evenly. Many professionals combine twisting with circular motion or back-and-forth strokes for a complete clean. This technique works for metal, glass, or plastic tubes, depending on the brush type.

Extra Tips for Professionals

- Check brushes regularly and replace worn-out bristles.

- Rinse brushes after each use to prevent cross-contamination.

- Choose brushes with sturdy handles for better grip.

- Store brushes upright to keep bristles in shape.

- For very tough residues, combine brushing with a safe chemical cleaner.

Final Thoughts: Keep Tubes Clean with Ease

Cleaning tubes properly isn’t just about effort—it’s about using the right technique and tools. High-quality tube cleaning brushes, including specialized brushes with shank, make the process faster, easier, and more reliable. Professionals who want consistent, durable results trust products from Hight Brush.

Their wide range of brushes is designed to handle various tube sizes and shapes, making tough cleaning tasks simpler. With the right brushes from Hight Brush, your tubes stay clean, equipment lasts longer, and every job runs smoothly.