Why Tube Brushes Outperform Cotton Swabs in Tight Spaces?

Cleaning tight spots can be tricky. Many people grab cotton swabs and hope for the best. But anyone who has tried cleaning narrow tubes or tiny pipes knows swabs often fall short. That’s where tube brushes come in. They are made for precision, speed, and durability. Whether it’s industrial machinery, plumbing, or hobby projects, these brushes handle jobs that swabs just can’t.

-

Better Reach, Every Time

Cotton swabs are soft and flexible, which sounds good. Until they bend, break, or leave behind fibers. Tube brushes for cleaning are designed to stay firm. Their bristles reach the inside of pipes, grooves, and tight corners without collapsing. You can scrub, twist, and move them around without worrying about missing a spot. A well-chosen brush for tube cleaning gets deep into areas swabs can’t touch.

-

Materials for Every Job

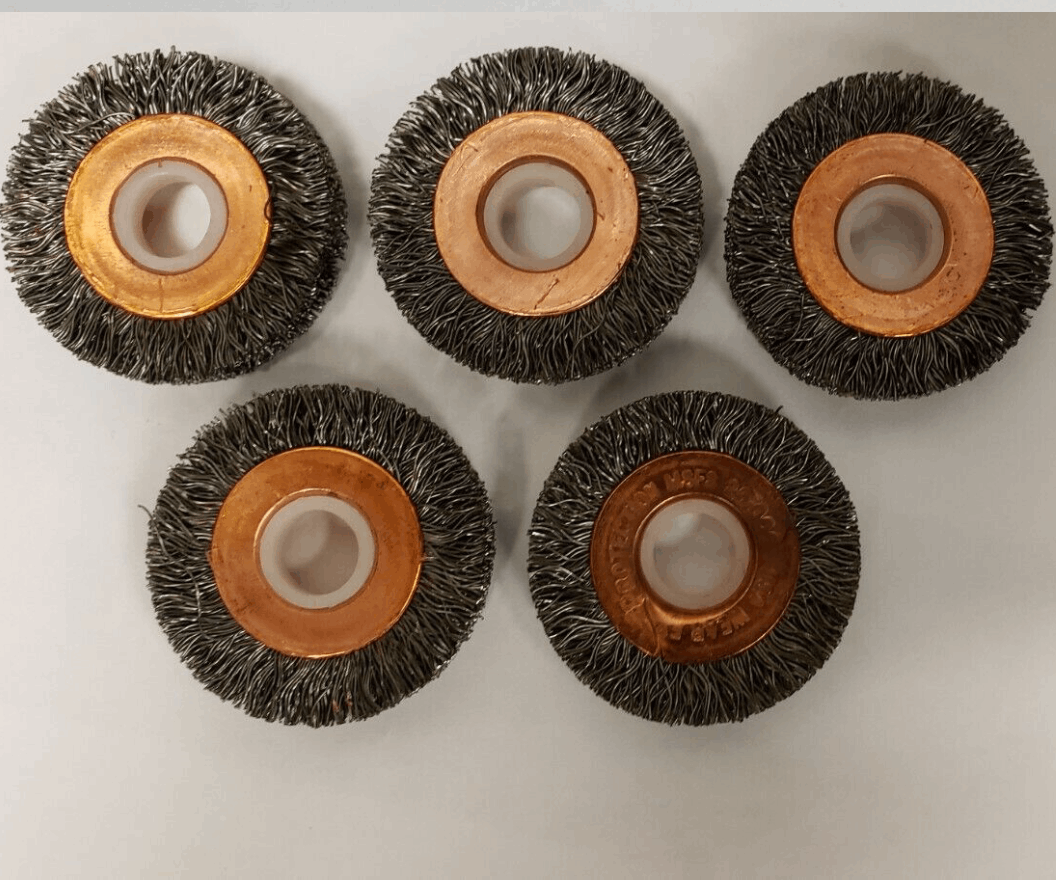

One big advantage of tube brushes is the variety of materials. Soft nylon brushes work well on delicate surfaces. Steel or brass bristles tackle tough grime. For specialized jobs, like plumbing, a copper tube cleaning brush removes rust and mineral deposits safely. Cotton swabs simply don’t offer this range of options. They are limited to light dusting and small smudges, not serious cleaning.

-

Speed and Efficiency

Cleaning with swabs takes time. Each one covers only a tiny area and needs to be replaced often. Tube brushes cover more surface area in fewer passes. They adapt to different diameters and shapes, making tasks quicker and easier. From narrow lab glassware to long industrial pipes, these brushes get the job done faster, saving both effort and frustration.

-

Built to Last

Cotton swabs are meant to be thrown away after one use. Tube brushes, on the other hand, are reusable. High-quality brushes hold their shape and keep working effectively even after multiple uses. Industries rely on them for daily cleaning because they last. Investing in a proper tube brush for cleaning reduces waste and saves money in the long run.

-

Specialized Uses

Tube brushes are versatile. Labs use them for pipettes and test tubes. Musicians rely on them for cleaning instrument tubing. Hobbyists use them for engines, firearms, and models. A copper tube cleaning brush handles stubborn deposits in plumbing without damaging the metal. Whatever the application, tube brushes are more precise, reliable, and thorough than swabs.

Tips for Best Results

Choosing the right brush makes all the difference.

- Pick the right size: Match the brush diameter to the tube for better contact and cleaning.

- Choose the right material: Different surfaces need different bristle types. Soft for delicate tubes, stiff for tougher debris.

- Consider bristle stiffness: Too soft won’t clean well; too stiff may damage the tube.

- Clean after use: Rinse off residue to prevent buildup on the brush.

- Dry completely: Moisture can damage bristles or cause rust.

- Store properly: Keep brushes in a dry, safe place to maintain shape and performance.

- Replace when worn: Overused brushes lose efficiency, unlike cotton swabs that wear out quickly.

- Consistency matters: Regular maintenance ensures each use is effective and smooth.

Upgrade Your Cleaning Game with Hight Brush

Cotton swabs might handle quick fixes, but when it comes to tight spaces, stubborn debris, or repeated use, they just don’t cut it. Tube brushes for cleaning are built to reach where swabs can’t. They bend, scrub, and adapt to every curve, making cleaning faster, smarter, and more thorough. Using the right brush for tube cleaning, like a copper tube cleaning brush, means less effort and better results every time.

For anyone serious about quality and reliability, High Brush is a go-to source. Their wide range of abrasive and tube brushes covers everything from delicate instruments to heavy-duty industrial tasks. Every brush is designed to last and perform consistently. With Hight Brush, you get tools that make even the toughest cleaning jobs easier, precise, and stress-free.