How Wire Wheel Brushes Outperform High-Tech Finishing in Certain Jobs?

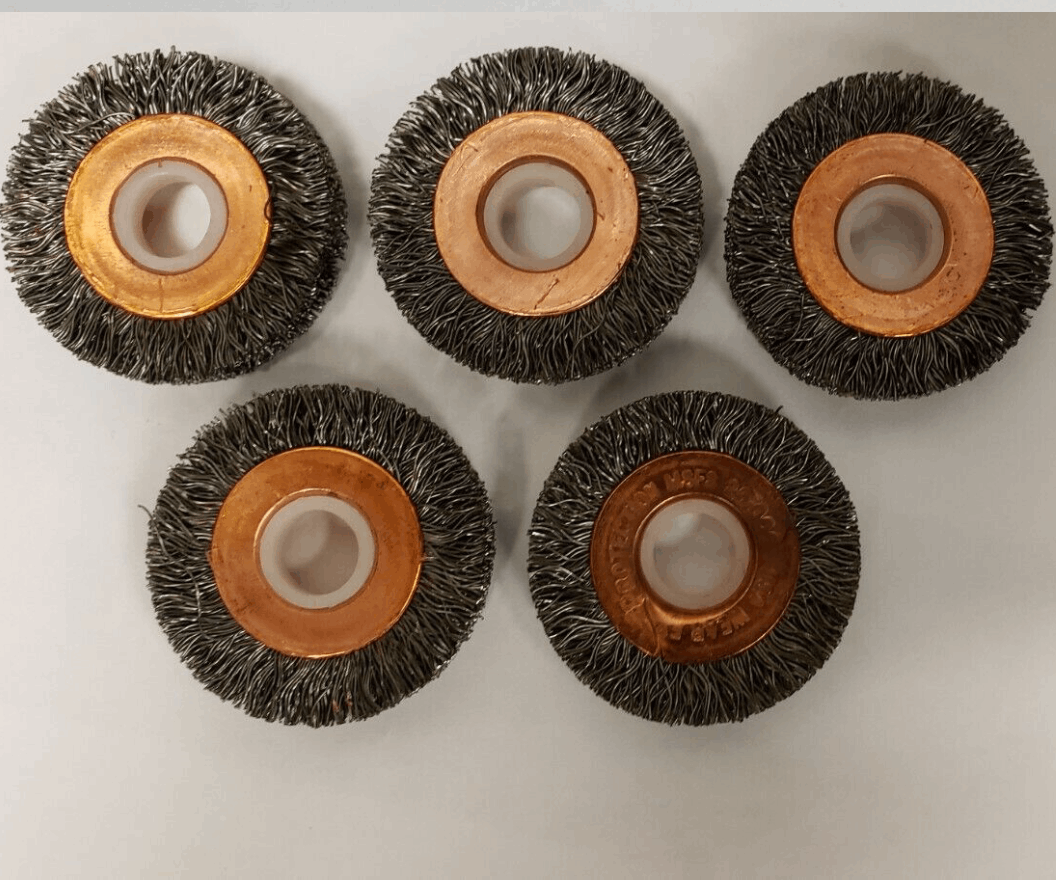

When it comes to cleaning and finishing metal surfaces, not all tools are the same. High-tech finishing machines promise speed and automation, but sometimes a simple wire wheel brush does the job better. From removing rust to smoothing rough edges, wire wheel brushes remain a reliable choice in workshops and repair shops.

These brushes are versatile. With options like wire wheel brush adaptors and wire brush wheel for drill, users can handle everything from small repairs to large metal surfaces. Unlike automated machines, wire brushes give you control. You can adjust pressure, angle, and speed for a consistent finish.

-

Flexibility for Every Surface

High-tech machines often work in set patterns. This works for flat, uniform surfaces. But what about corners, grooves, or uneven edges? Wire wheel brushes bend and adapt. They reach areas machines might miss.

Hight Brush offers products like wire wheel brush grinders and adaptors designed to cover both big and small surfaces. Their flexibility ensures every edge and curve gets cleaned without damaging the material.

-

Removing Rust and Scale

Old metal often has rust, paint, or scale. Machines may struggle here. They can even scratch or damage the surface. Wire wheel brushes handle these challenges well. Their bristles reach into small pits and tight spots to remove buildup safely.

Using a wire brush wheel for a drill, operators can clean vertical surfaces, odd shapes, or tight edges. Direct control ensures thorough cleaning, something many machines can’t achieve.

-

Cost-Effective and Efficient

Wire wheel brushes are also budget-friendly. One brush can last for many projects if used correctly. High-tech machines need electricity, expensive parts, and calibration. Brushes require almost no setup, making them perfect for workshops or on-site jobs.

Durable brushes from Hight Brush show that simple tools can outperform expensive machines, especially for specialized or one-off tasks. They save time, money, and effort while still delivering quality results.

-

Adaptable for Different Tasks

Wire wheel brushes are highly adaptable. You can switch brush types, adjust pressure, or use wire wheel brush adaptors to fit drills or grinders. One brush can work on steel, aluminum, copper, or stainless steel, making it more versatile than many machines.

Specialized brushes also fit into this system. Some are designed for delicate deburring or surface blending. Their flexibility makes them useful in metal fabrication, repair, and finishing projects.

Tips to Extend Brush Life

Getting the most out of your wire brushes doesn’t have to be complicated. Small habits make a big difference.

- Clean After Use: Remove metal debris and dust after every job. This prevents buildup that can damage bristles.

- Store Properly: Keep brushes in a dry place. Moisture can cause rust, reducing performance and lifespan.

- Inspect Regularly: Look for worn, bent, or uneven bristles. Replacing or rotating brushes ensures consistent results.

- Use Correct Type: Match the brush to the material and task. Using the wrong type can wear it out faster and harm the surface.

- Gentle Handling: Avoid pressing too hard. Let the bristles do the work.

Simple care steps like these make wire brushes last longer, maintain efficiency, and reduce costs. Unlike complex machines, they are easy to manage and replace when needed.

Why Wire Wins Over Machines?

Sometimes, machines just can’t match the finesse of a human touch. Wire wheel brushes excel where precision, control, and adaptability are key. From tight corners to uneven metal surfaces, and even rust-heavy spots, brushes like a wire brush wheel for drill, wire wheel brush adaptors, and wire wheel brush grinders get the job done with ease.

Hight Brush brings you a range of top-tier wire brushes built to last. They combine durability, performance, and versatility, making even tough jobs feel effortless. With Hight Brush, you get tools that work smart, save time, and let you finish like a pro every time.

Ready to upgrade your tools? Explore Hight Brush’s full range today and tackle every project with confidence.