Safety Precautions When Working with Wire End Brushes

Wire end brushes are a common tool in metalworking and industrial applications. They clean, deburr, polish, and prepare surfaces quickly. However, their use comes with safety risks that cannot be ignored. Wire end brush injuries occur when users neglect protective measures or proper handling techniques. This article will guide you through practical safety precautions for using these brushes efficiently and safely.

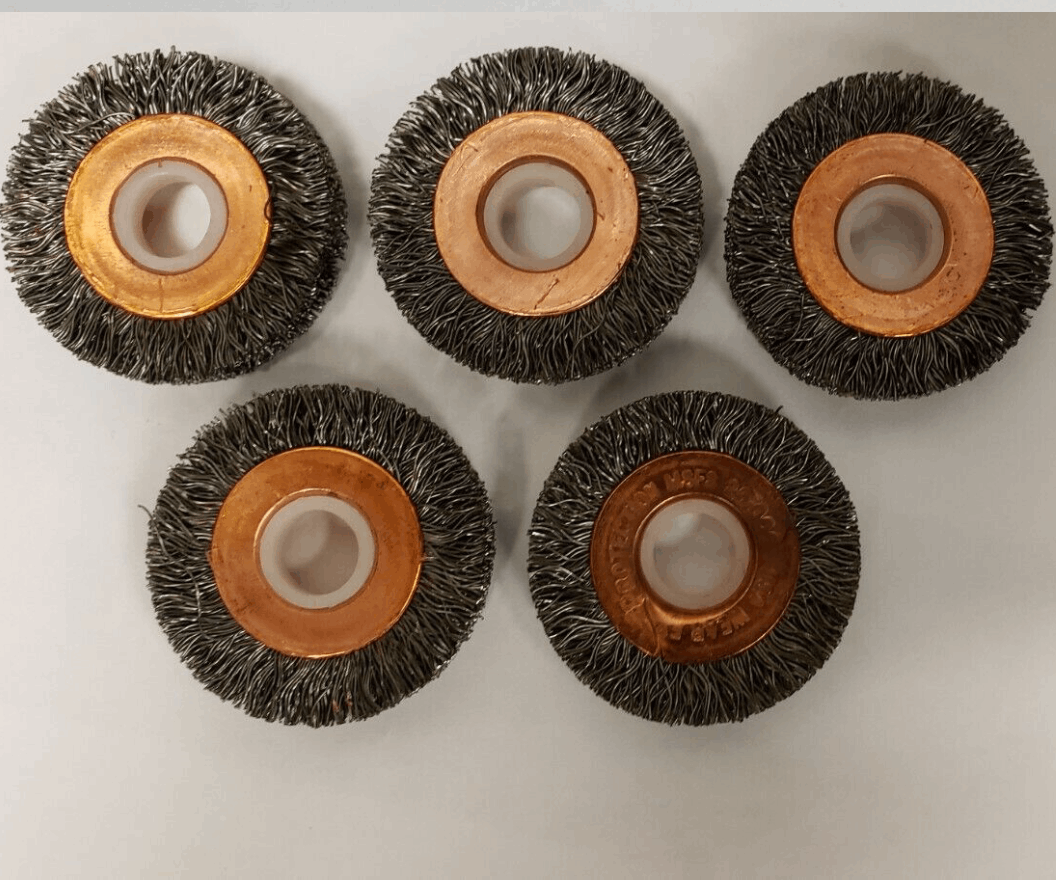

Understanding the Types of Wire End Brushes

Wire brushes come in different forms depending on the application. The most common types include:

- Crimped wire end brush – This type has wavy wires that provide gentle cleaning and surface finishing. They are ideal for delicate tasks like removing rust without damaging the base material.

- Solid wire brushes – They are stiff and tough, designed for heavy-duty cleaning and metal preparation.

- Knot wire end brush – These have twisted wire clusters, offering aggressive performance for tough surface cleaning and deburring. We will touch more on them in the conclusion.

Knowing the brush type helps in selecting the correct protective measures.

Wear Proper Protective Gear

When using wire brushes, your safety starts with personal protection:

- Eye Protection: Always wear safety goggles or a full face shield. Wire fragments can fly off at high speeds and cause serious eye injuries.

- Hand Protection: Gloves reduce the risk of cuts or punctures from stray wires. Leather gloves are preferred for durability.

- Clothing: Avoid loose clothing that can get caught in the rotating brush. Long sleeves made of thick material provide added protection.

- Respiratory Protection: Dust and metal particles are common. Use a mask or respirator to prevent inhalation.

These precautions may seem basic but are critical to preventing serious injuries.

Inspect the Brush Before Use

Before starting any project, examine your wire end brush carefully:

- Check for loose, bent, or broken wires.

- Ensure the brush is correctly mounted on the tool.

- Verify that the tool’s speed matches the brush’s recommended rotation limit.

Using a damaged brush increases the risk of wire fragments detaching during operation. A quick inspection can save you from serious harm.

Secure Your Workspace

A safe workspace reduces accidents significantly:

- Keep your work area clean and free of unnecessary items.

- Ensure that no one is standing close to your operating area. Flying debris can cause injuries to bystanders.

- Work on stable surfaces to prevent slips and accidents.

Organizing your workspace also improves efficiency, allowing you to focus fully on the task.

Proper Handling Techniques

How you handle a crimped wire end brush affects both safety and efficiency:

- Avoid excessive pressure. Let the brush do the work. Pushing too hard increases wire breakage and tool wear.

- Maintain the correct angle. Holding the brush too steep or too flat can reduce cleaning effectiveness and increase wire loss.

- Keep a steady speed. Rapid changes in speed or direction can cause wires to fly off.

Practicing these techniques ensures smoother work and reduces the risk of accidents.

Maintenance and Storage

Proper care of your wire brushes extends their life and keeps you safe:

- Clean the brush after use to remove metal particles or debris.

- Store brushes in a dry area to prevent rusting.

- Replace brushes once wires are worn or bent. Using worn brushes can compromise safety.

A little attention to maintenance goes a long way in preventing injuries.

Emergency Preparedness

Accidents can happen despite precautions. Be ready:

- Keep a first-aid kit nearby.

- Know the procedure for dealing with eye injuries or punctures.

- Train workers or colleagues on emergency response specific to brush use.

Being prepared minimizes harm and ensures quick recovery.

The Final Thoughts:

Safety should guide every choice. While knot wire end brush offers aggressive cleaning power, it also requires extra care. Always assess your task, select the appropriate brush, and follow safety measures.

At Hight Brush, we supply a wide range of industrial brushes, including wire end brushes, crimped wire brushes, knot wire brushes, and more. We deliver superior products and services both in the USA and internationally. Our skilled engineers design brushes for every application right from simple scrub brushes to specialized industrial solutions.

We prioritize relationships with our clients, ensuring reliable support before and after sales. Our brushes are trusted for quality, durability, and performance across industries. Explore our offerings at hightbrush.co and experience why Hight Brush is a market leader in Texas for industrial brushes.

FAQs

1. What is the main risk of using a wire end brush?

The primary risk is flying wire fragments, which can cause eye or skin injuries. Proper protection is essential.

2. How do I choose between a crimped wire end brush and a knot wire end brush?

Choose a crimped wire brush for gentle cleaning or polishing and a knot wire brush for heavy-duty deburring or aggressive cleaning.

3. Can wire brushes be used on all metals?

Yes, but softer metals may require crimped wire brushes to avoid scratching or damage.

4. How often should wire brushes be replaced?

Replace brushes when wires are bent, broken, or worn down to ensure safety and efficiency.

5. Does Hight Brush supply brushes internationally?

Yes, Hight Brush delivers high-quality industrial brushes both within the USA and abroad, supporting a wide range of industrial applications.