Don’t Overlook the Inside: Deburring Hidden Features in Medical Parts

In medical device manufacturing, even tiny flaws can cause big problems. A small burr inside a bone screw or catheter hub might seem harmless—but it can affect how the part works or even put patients at risk. That’s why internal deburring matters just as much as surface finishing.

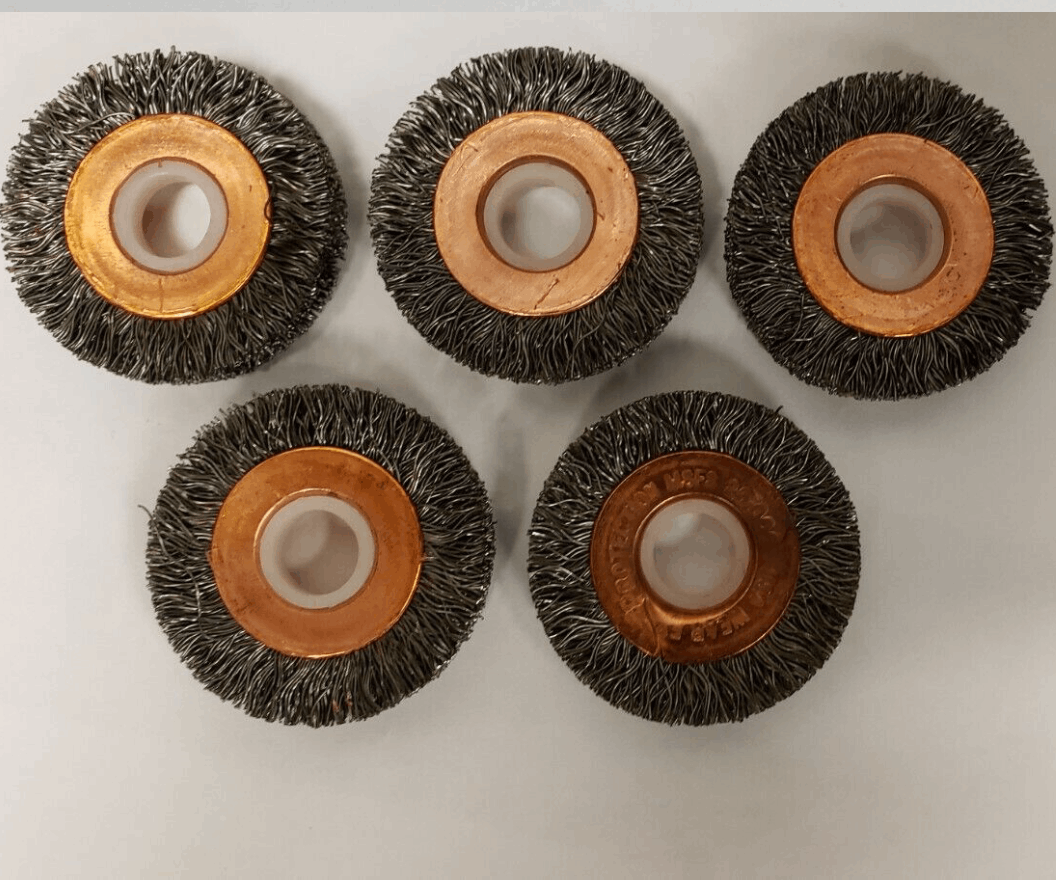

While outer edges are easy to clean, inner areas are often ignored. But many manufacturers now use medical device brushes to reach and clean these hidden spaces—quickly, safely, and without damaging the part.

The Burrs You Can’t See Still Matter

Burrs are rough metal bits left behind after cutting or drilling. On the outside, they’re easy to spot. On the inside, not so much. But in medical parts, internal burrs can cause friction, block fluids, or scrape tools that pass through them.

In some cases, loose burrs may even break off and lead to contamination. This is why internal finishing isn’t just about how a part looks—it’s about making sure it works safely and smoothly.

That’s where medical device brushes come in. These tools are designed to reach tight spaces like small tubes, holes, and corners to remove burrs and smooth the surface.

Why Common Tools Don’t Work Inside

Traditional tools like files or sandpaper don’t work well in narrow holes or deep channels. Blasting can clean outer surfaces, but the abrasive material might not reach all internal areas. Worse, it could leave particles behind.

This is why many teams use brushes for closed-end holes. These brushes are flexible and can reach deep inside parts to remove burrs gently—without changing the shape or size of the part.

Why These Brushes Are a Better Option

Using medical device brushes for internal deburring offers many benefits:

- Reaches tight and deep areas

- Removes burrs without scratching the part

- Keeps the original shape of the part

- Saves time and reduces manual work

- Improves product safety and quality

These brushes are easy to use and can even be added to automated setups, which helps speed up production.

Where Internal Deburring Is Most Important

Some medical parts must have clean and smooth insides to work properly. These include:

- Bone screws – Burrs can stop proper threading

- Catheters and guide tubes – Rough spots can block movement or damage other tools

- Cannulas – A burr can catch fibers or irritate tissue

- Blind threaded holes – Burrs can cause screw alignment problems

Choosing the right brush helps prevent these issues and improves how the device performs.

Finishing the Job Right—Inside and Out

A medical part might look flawless on the outside, but hidden burrs inside can still cause trouble. Internal finishing is not optional—it’s essential for both safety and function. That’s where medical device brushes prove their worth, especially when it comes to reaching those tricky spots.

For teams looking to clean small holes, tubes, or deep channels without damaging the part, Hight Brush offers practical tools that get the job done. Their range of brushes for closed end holes, like Valve Guide Brushes and shank-mounted tube brushes, are designed to meet the needs of modern medical manufacturing—simple to use, built for tight spaces, and ready for clean results.

To keep your parts burr-free where it counts, tools from Hight Brush offer the right fit.