Microabrasive Brushes with Shank: Small Tools That Make Aerospace CNC Work Smoother

A single burr on a machined part can ground an entire aircraft. In aerospace, even tiny flaws can become big problems. That’s why surface finishing is more than just an afterthought—it’s a vital part of the manufacturing process.

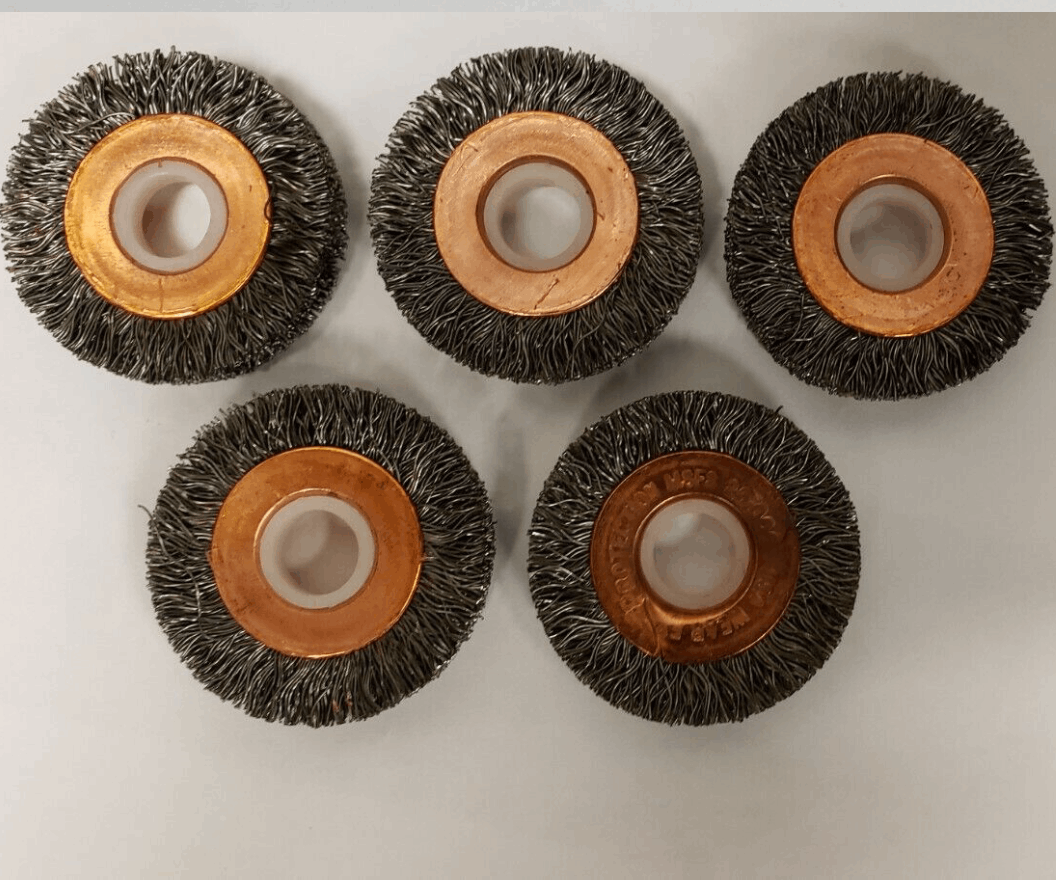

And when it comes to removing those small imperfections quickly and safely, microabrasive brushes are often the tool of choice. Designed to work with CNC machines, these brushes offer a simple, effective way to finish parts without slowing production down.

What Makes These Brushes Different?

Standard deburring tools can be too rough. Sanding pads wear out fast. But microabrasive brushes offer something better. They’re built with abrasive grains embedded into flexible filaments. These filaments gently smooth edges, clean up burrs, and leave surfaces ready for inspection.

Unlike traditional tools that might gouge or distort delicate aerospace parts, these brushes clean without cutting corners—literally.

They also do something else really well: they fit right into the CNC workflow. No need to take parts off the machine. No extra steps. Just load the brush, run the program, and let it do the work.

Why Shank-Mounted Brushes Fit So Well in Aerospace

In fast-paced CNC environments, tools must be quick to load and easy to control. That’s why brushes with shank attachments are such a good fit. They slot directly into the machine spindle, just like a cutting tool.

That means you can finish surfaces right after machining—without stopping production or adding more hands to the job. For aerospace parts with tight tolerances and tricky internal features, that’s a big win.

These brushes can also reach into spots where traditional tools can’t—like counterbores, threads, and blind holes. That’s especially useful in aircraft components that have complex designs or hidden channels.

Built for Titanium, Inconel, and Aerospace Alloys

Aerospace components are often made from tough metals like titanium, aluminum alloys, and Inconel. These materials are strong—but they’re also prone to sharp burrs and heat buildup during machining.

Microabrasive brushes offer a gentle yet effective way to finish these surfaces without causing damage. The abrasive filaments remove rough edges gradually, which helps avoid micro-cracks or deformation.

Unlike rigid tools, these brushes adapt to the part’s shape, making them ideal for complex geometries. Whether it’s a thin aluminum panel or a dense titanium bracket, the brush provides a clean finish without altering dimensions.

That’s a big plus in aerospace, where even minor defects can affect performance or safety. These brushes keep parts clean and compliant—without added risk.

Benefits That Go Beyond the Finish

Using micro abrasive brushes in aerospace CNC machining offers several clear advantages:

- Reduces manual labor by allowing in-machine finishing

- Lowers rework rates by removing burrs without damaging parts

- Keeps part geometry intact with controlled, non-aggressive brushing

- Improves surface consistency for better visual and dimensional quality

- Speeds up inspection by delivering clean, uniform finishes

- Cuts production delays with fewer defects and smoother workflows

- Fits directly into CNC programs, eliminating extra handling

These small tools make a big difference by helping manufacturers run cleaner, leaner, and more dependable operations—right from the machine.

One Small Tool, Many Big Wins

In aerospace CNC machining, finishing tools don’t need to be big or complex. They just need to get the job done—cleanly and efficiently. That’s exactly what micro abrasive brushes do. They help meet strict surface standards without damaging the part or slowing production.

With shank-mounted designs and CNC compatibility, these brushes are ideal for high-demand environments. At Hight Brush, tools like the RadialBrush-CB are built for tasks like edge blending and surface finishing on aerospace metals. They’re easy to use, durable, and designed for consistent results—part after part.

These small tools play a big role in helping aerospace shops run smoother, faster, and more reliably—one burr-free part at a time.