How Deburring Industrial Brushes Improve?

Manufacturers lose up to 30% of productivity due to inefficient finishing processes. This is where deburring industrial brushes play a crucial role. These brushes are designed to remove burrs, sharp edges, and unwanted material from metal, plastic, or composite parts, saving time and improving product quality. By streamlining finishing, they help manufacturers maintain consistent output while reducing errors and material waste.

Understanding Deburring Industrial Brushes

Deburring industrial brushes are specialized tools used to smooth rough edges or remove tiny metal fragments left after machining. Unlike manual sanding or filing, these brushes offer speed and uniformity. They come in different forms, including wire brushes, nylon brushes, and abrasive brushes, each tailored for specific materials and applications.

These brushes are widely used in sectors like automotive, aerospace, and electronics, where precision is important but manual finishing is time-consuming. They not only enhance efficiency but also improve worker safety by reducing contact with sharp edges.

Why CNC Operations Benefit from Deburring Brushes

CNC machines are the backbone of modern manufacturing. However, machining metal, plastic, or composites often leaves burrs that compromise assembly or product quality. Using deburring brushes for CNC, manufacturers can integrate finishing directly into their production line.

This integration reduces downtime because parts do not need to be moved to a separate finishing station. The brushes can handle complex shapes, including slots, holes, and threads, ensuring every piece meets quality standards. By doing this, companies achieve faster throughput and minimize rework.

Time and Cost Savings in Manufacturing

Using deburring industrial brushes results in noticeable time and cost savings. Manual deburring requires more labor hours and increases the chance of mistakes. Automated or machine-integrated brushes can operate continuously, cutting finishing times by up to 50% in some applications.

In addition to time savings, these brushes reduce tool wear and material waste. Unlike grinding wheels or files, brushes leave a smoother finish with minimal loss of raw material. This translates directly into lower production costs and improved profitability.

Quality and Consistency with Every Pass

One of the biggest advantages of using deburring brushes for CNC or manual stations is consistent quality. Each part receives the same finishing, regardless of its complexity. Wire or abrasive brushes remove burrs without damaging edges, leaving a clean, polished surface.

Consistent finishing improves assembly accuracy and extends the life of the final product. In industries like medical devices or electronics, even minor imperfections can cause failure. Industrial brushes prevent this, ensuring reliability and enhancing brand reputation.

Flexibility Across Materials and Shapes

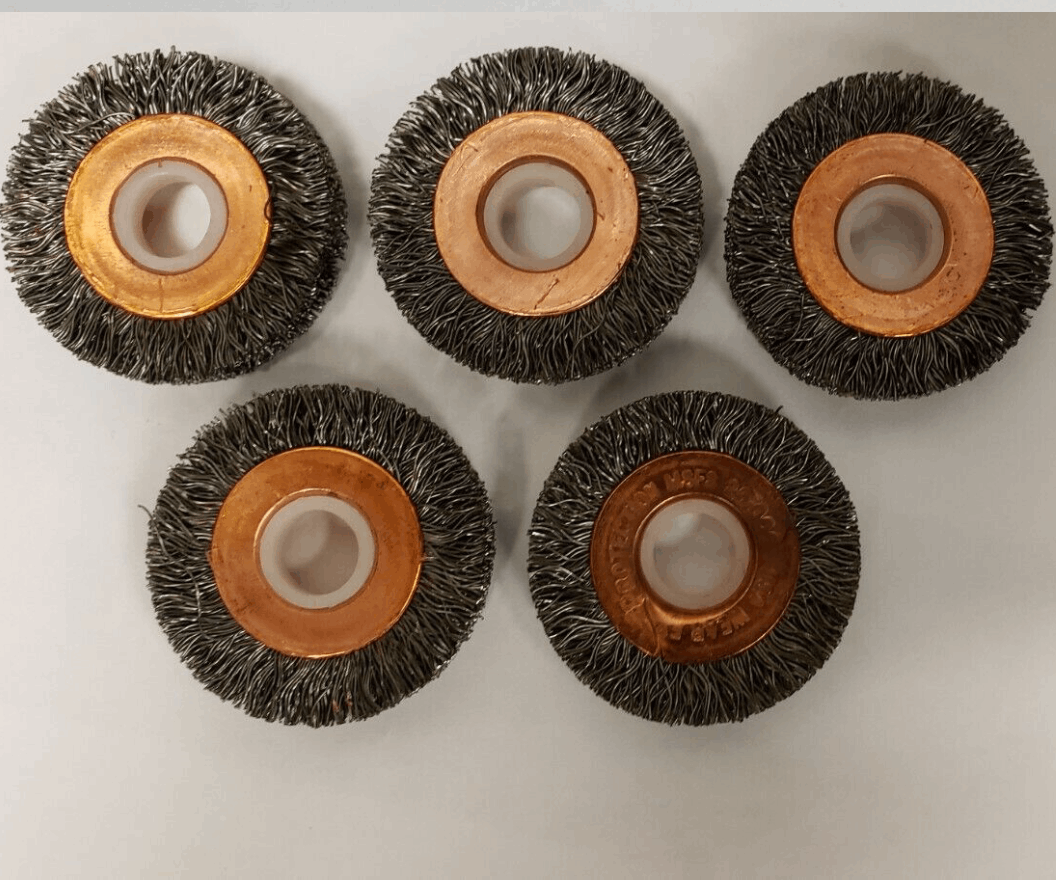

Deburring industrial brushes are highly versatile. They can handle metals, plastics, composites, and even delicate materials without bending or scratching surfaces. Brushes are available in multiple shapes and sizes like cup, wheel, or end brushes, allowing manufacturers to reach tight spaces or complex geometries efficiently.

This flexibility means one manufacturing line can handle multiple products without changing tools, saving time and reducing inventory requirements. Versatile brushes also allow engineers to experiment with new materials without worrying about finishing constraints.

Safety Benefits for Workers

Manual deburring can be dangerous. Sharp edges, metal shards, and repetitive motion can lead to injuries. Industrial brushes provide a safer alternative by automating the process and minimizing direct contact with hazardous surfaces.

Operators can focus on machine monitoring and quality control rather than handling sharp parts. Over time, this reduces workplace injuries and improves overall employee satisfaction, which also contributes indirectly to manufacturing efficiency.

Easy Maintenance and Long-Term Performance

Another advantage of deburring brushes for CNC is their long lifespan. At Hight Brush, we design high-quality industrial brushes for durability. They maintain performance over thousands of cycles, which helps us reduce replacement frequency and maintenance costs for our clients.

We make maintenance simple: by cleaning debris from brushes and occasionally replacing worn bristles, we ensure consistent performance. This reliability allows our team and clients to plan production schedules without unexpected delays, further improving overall efficiency.

Key Reflections

If you’re seeking reliable, high-performance industrial brushes, Hight Brush is the market leader in Texas. We provide a wide variety of brushes, including deburring brushes for CNC, platers brushes, artist paint brushes, flue brushes, wire wheel brushes, and tube cleaning brushes. Our team of skilled engineers can design brushes for any application, from simple plastic handles to complex industrial requirements.

We serve customers across the USA and internationally, prioritizing trust and long-term relationships. Our services go beyond sales, ensuring after-sales support and technical guidance. Choose High Brush for a partner who values quality, innovation, and efficiency.

We serve customers across the USA and internationally, prioritizing trust and long-term relationships. Our services go beyond sales, ensuring after-sales support and technical guidance. Choose High Brush for a partner who values quality, innovation, and efficiency.

FAQs

1. What are deburring industrial brushes used for?

They remove burrs, sharp edges, and debris from metal, plastic, and composite parts, ensuring smooth finishes.

2. Can deburring brushes be used with CNC machines?

Yes, deburring brushes for CNC can be integrated into production lines for efficient, uniform finishing.

3. How do abrasive brushes improve manufacturing efficiency?

They save time, reduce errors, minimize material waste, and improve product quality.

4. What materials can industrial brushes handle?

They work on metals, plastics, composites, and even delicate materials without causing damage.

5. Why choose Hight Brush for industrial brushes?

With 25 years of experience, high-quality products, custom solutions, and global service, Hight Brush delivers reliability and performance for all industrial brush needs.