Copper pipes are a common choice in many homes because they are durable and efficient at carrying water. However, over time, mineral buildup, dirt, and corrosion can cause problems in your plumbing system. Cleaning your copper pipes regularly can help prevent clogs and extend the lifespan of your pipes. Using the right tools like a copper pipe brush can make this job easier and more effective. Here’s a simple guide on how to clean your copper pipes.

Why Clean Copper Pipes?

Copper pipes can accumulate mineral deposits, especially in areas with hard water. This buildup can restrict water flow, causing a decrease in water pressure. Additionally, if left unchecked, corrosion may form, leading to leaks or pipe damage. Regular cleaning can help maintain proper water flow and prevent the need for costly repairs.

What You’ll Need?

Before you start cleaning your copper pipes, gather these tools:

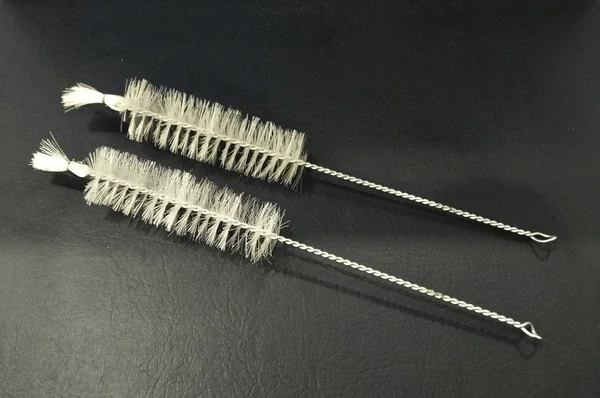

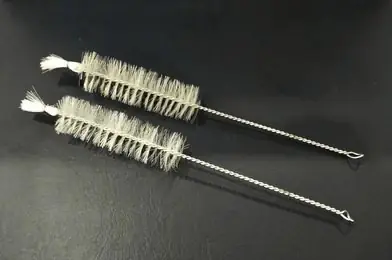

- Copper pipe brush: A brush designed specifically to clean the inside of copper pipes.

- Pipe brush cleaner: A cleaning solution or vinegar that helps dissolve mineral deposits.

- Water source: A nearby sink or hose to rinse the pipes.

- Protective gloves: To keep your hands safe from dirt or cleaning chemicals.

- Bucket or container: To catch any water or debris.

Step 1: Turn Off the Water Supply

The first step is to turn off the water supply to the pipes you’re cleaning. Find the main shut-off valve and turn it clockwise to stop the flow of water. After that, open a faucet to release any leftover water pressure in the pipes. This will ensure that no water comes out while you are working.

Step 2: Remove the Pipe (If Needed)

If you need to clean a section of pipe that’s hard to reach, you may need to remove it from the system. Use a wrench or pliers to disconnect the pipe from its fittings. Keep a bucket or container underneath the pipe to catch any remaining water that may spill out.

Step 3: Clean with the Copper Pipe Brush

Now, it’s time to clean the inside of the copper pipe. Take the copper pipe brush and insert it into one end of the pipe. Gently scrub the interior of the pipe by moving the brush back and forth. This will help loosen any dirt, corrosion, or mineral deposits stuck inside.

If the pipe is long, you might need a longer brush or an extended handle. Be gentle with the brushing to avoid damaging the pipe.

Step 4: Use a Pipe Brush Cleaner

For pipes that have heavy mineral deposits, using a pipe brush cleaner can help. You can either buy a commercial cleaner or use a natural alternative like white vinegar. Pour the cleaner into the pipe and let it sit for 15 to 20 minutes. The cleaner will break down the mineral buildup, making it easier to remove.

After the cleaner has had time to work, use the copper pipe brush again to scrub away the loosened deposits.

Step 5: Rinse the Pipe

After scrubbing the pipe, rinse it thoroughly with clean water. You can either flush water through the pipe or use a hose to rinse away any remaining cleaner and debris. Make sure to rinse until the water runs clear, leaving the pipe free of any cleaning solution or buildup.

Step 6: Reconnect the Pipe

If you removed the pipe for cleaning, reconnect it to the plumbing system. Align the pipe with its fittings and tighten the connections using pliers or a wrench. Ensure that the pipe is securely connected to avoid leaks.

Step 7: Turn the Water Back On

Once the pipe is reconnected and cleaned, turn the water supply back on. Open the faucet to check that the water flows freely and that the pressure has returned to normal. If everything is working correctly, your copper pipes are now clean and in good condition.

Final Thoughts

Cleaning your copper pipes is an essential part of maintaining a healthy plumbing system. Using the right tools, such as a copper pipe brush makes the process much easier and more effective. By following these simple steps, you can improve water flow, prevent clogs, and extend the lifespan of your pipes. If you’re looking for high-quality brushes for your cleaning needs, Hight Brush is a trusted supplier, offering a wide variety of industrial brushes, including specialized copper pipe brushes. Contact Hight Brush today to find the right brush for your plumbing maintenance needs.