If you’ve ever stumbled across an old piece of furniture with intricate details and a worn-out finish, you’ve likely thought about restoring it. Whether it’s a cherished family heirloom or a flea market find, restoring antique furniture can breathe new life into a beautiful piece. One of the unsung heroes of furniture restoration is the disc sanding brush. This tool helps preserve the beauty of your antique furniture while giving it the care it deserves.

How Do Disc Sanding Brushes Help?

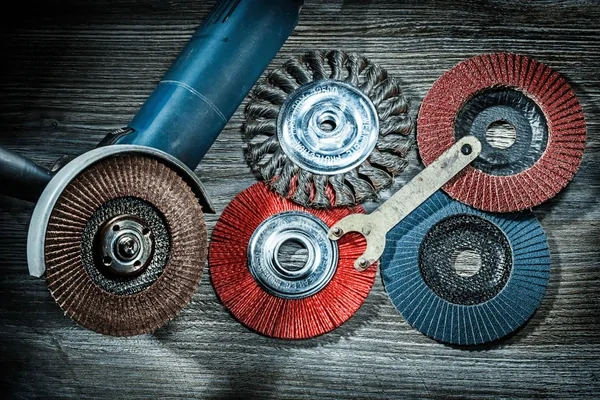

When it comes to antique restoration, you don’t want to rush the process. Disc sanding brushes give you more control over the sanding process, allowing you to go slow and steady. Whether you’re removing an old layer of paint, varnish, or dirt, these brushes help you achieve a smooth finish. Because they’re mounted on drills or rotary tools, they make the job quicker and more efficient, which is especially helpful when you’re working on larger pieces.

The real magic of disc sanding brushes is in their versatility. These brushes can be used for everything from cleaning grime and dirt to sanding down old finishes. No matter how intricate or detailed the furniture is, these brushes can handle it all, offering you the flexibility you need for different restoration tasks.

Tips for Using Disc Sanding Brushes on Antique Furniture

- Assess the Condition: Before you begin, take a good look at the piece of furniture. Is the wood still in good condition, or is it fragile and easily damaged? This will help you choose the right brush for the job.

- Choose the Right Brush: Not all disc sanding brushes are created equal. You’ll want to select the right type of brush based on the material and condition of the wood. Softer brushes are best for delicate pieces, while firmer brushes can handle tougher surfaces.

- Work Gently: Start sanding gently. You’re not trying to strip the wood, just smooth out imperfections. Sand with the grain of the wood, and always go slow. It’s easier to correct small mistakes than to fix deep gouges caused by overzealous sanding.

- Refine the Finish: Once you’ve done the main sanding, use finer disc sanding brushes to refine the finish. This will help remove any rough patches and leave a smooth surface ready for staining or sealing.

- Wipe Down: After you finish sanding, take a clean, soft cloth and wipe down the piece. This will remove any dust or debris left behind, ensuring your new finish adheres properly.

The Benefits of Using Disc Sanding Brushes for Furniture Restoration

- Gentle on Antique Pieces: One of the main advantages of disc sanding brushes is that they’re gentle on older, more delicate wood. They remove dirt, grime, and old finishes without gouging or causing further damage.

- Time-Saving: Restoration projects can take a long time, but disc sanding brushes speed up the process. With their ability to handle larger areas more quickly, you can spend more time focusing on the finer details of your piece.

- Precision: If you’ve ever tried to clean or restore furniture with sandpaper, you know how difficult it can be to maintain control. Disc sanding brushes offer precision and stability, making it easier to focus on detailed parts of the furniture without accidentally sanding the wrong areas. Using brushes with a shank further enhances control and stability, especially in tight spaces or intricate designs.

- Versatility: From removing old finishes to polishing rough spots, disc sanding brushes are versatile tools that handle multiple tasks, making them an essential part of any restoration project.

In Summary: Bring Your Antiques Back to Life with Hight Brush

When it comes to restoring antique furniture, disc sanding brushes are your secret weapon for a flawless finish. At Hight Brush, we don’t just sell brushes—we provide tools designed with your specific needs in mind. Our high-quality products, crafted with a blend of cutting-edge technology and creative design, ensure a smooth, precise restoration process.

Best of all, we offer these premium brushes at prices that beat most supply stores. Ready to breathe new life into your antiques? Reach out to Hight Brush today and let us help you achieve the results you’re looking for!